Blacksmithing Question of the Day:

Does carbon steel rust?

Yes, carbon steel rusts or oxidizes. It lacks certain anti-corrosive elements that would prevent this.

To compare, stainless steel varieties have elemental additions like Chromium (Cr) and Nickel (Ni) that prevent oxidation (rust).

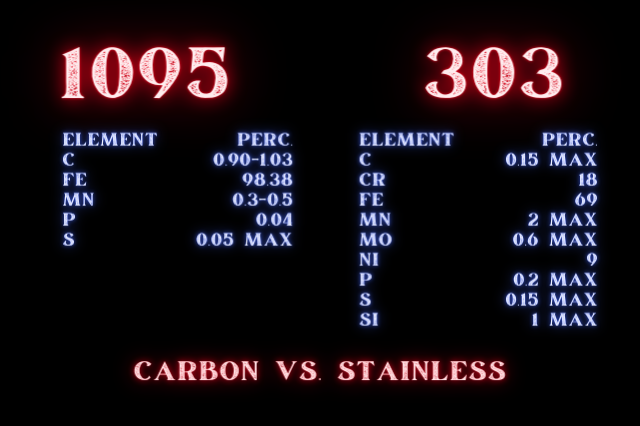

1095 Carbon Steel vs. 303 Stainless Steel

Here is a comparison table of the elements in 1095 carbon steel and 303 stainless steel:

At a glance, you can see that there are almost twice as many elements in 303 stainless steel as 1095 carbon steel.

What’s most notable however, is the large difference in Iron (Fe) content and the addition of large amounts of Chromium (Cr) and Nickel (Ni):

- 1095 steel is 98+ percent Iron.

- 303 Stainless is just 69 percent Iron.

- 1095 has no Chromium or Nickel.

- 303 has Chromium and Nickel in large amounts.

Iron is a very rust-prone material. By reducing a rusty element and adding in elements with anti-corrosive/anti-oxidative properties you achieve your goal.

You can prevent rust on carbon steel by adding a protective layer to the outside of the metal.

Some common examples are:

- Beeswax for hand-forged goods

- Oil for machine parts and hand-forged goods

- A spray-on clear coat like Rustoleum or Krylon

The use for the carbon steel will dictate what protective finish you apply.

- For food grade uses, a vegetable or plant oil is your best bet. (Yes, you can cook using carbon steel pans.)

- For traditional ironwork, beexwax is great for indoor items.

- Outdoor items may need a clear coat, spray paint, or powder coating to resist weather and salt.

Conclusion: Will Carbon Steel Rust?

Yes, it will. But you can protect it with waxes, oils, and spray-on finishes.

*Be sure to clean off any existing rust before applying these finishing techniques.

Further Reading:

Learn more about Stainless and Carbon Steel at OnlineMetals.com