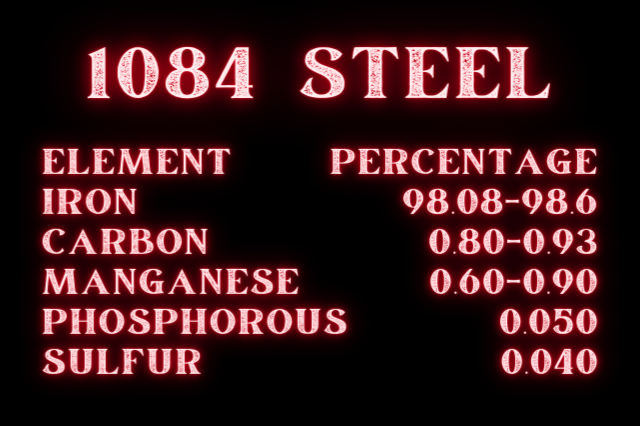

1084 steel is a widely used steel in the knife-making world. Its high carbon content makes it great for heat treating.

In this blog post, we will look at the unique properties of 1084 and why it is used to create knives known for their strength, sharpness, and versatility.

We will also provide resources for purchasing high quality 1084.

High Carbon Content for Hardness and Edge Retention

1084 is a steel alloy with 0.80 – 0.93% carbon, making it perfect for achieving a desirable hardness and excellent edge retention.

To compare, the steel you find at Home Depot or Lowes typically has 0.18% carbon in it or less.

These soft steels (under 0.45% carbon) aren’t “hardenable” so they don’t make good knives.

Knives made from 1084 can maintain their sharpness even after extensive use, allowing for precise and efficient cutting tasks.

Whether slicing through tough materials on a backpacking trip or performing delicate maneuvers, 1084 blades provide a reliable cutting edge.

Ease of Sharpening

One significant advantage of 1084 is its ease of sharpening.

This steel type responds well to sharpening tools, enabling blades to be honed to a razor-sharp edge with some practice.

This attribute is particularly important for outdoorsmen and bushcrafters, who prefer knives that can be easily maintained and sharpened to retain their optimal performance.

Our picks for sharpening:

Nicholson Flat Files – Amazon.com

Sharp Pebble Premium Whetstone – Amazon.com

Good Wear Resistance and Durability

1084 has excellent wear resistance, enabling knives made from this steel to withstand heavy usage without losing their sharpness.

The inherent durability of 1084 ensures that knives crafted from it can handle demanding tasks.

This durability makes 1084 knives reliable tools that can endure challenging conditions.

Rust and Corrosion – It’s Not Stainless Steel

It’s important to note that 1084 steel is not stainless, and therefore, it requires proper care and maintenance to prevent rust and corrosion.

Applying a thin coat of oil to the blade after each use and ensuring proper storage will help protect the steel and extend its lifespan.

Regular maintenance is crucial to ensure the longevity of knives made from 1084.

Conclusion – 1084 Steel

1084 steel stands as a popular choice in the realm of knife making due to its high carbon content, offering desirable hardness and edge retention.

This steel’s ease of sharpening and honing further enhances its appeal. Its wear resistance and durability make 1084 steel knives reliable tools for various cutting tasks.

Where to Buy 1084

Unfortunately, you won’t be able to walk into your local hardware store and buy 1084.

For the most options, we recommend ordering from OnlineMetals.

To order, here are the selections to make at OnlineMetals.com:

- Select Material: Carbon Steel

- Select Shape: Bar-Rectangle

- Select Alloy: 1084

- Select Thickness: Up to you, but we recommend in the range of 0.125 or 1/8″ thick for stock removal. Thicker for forging.

- Select Width: Currently they offer 1.5″, 2″, and 3″