A2 steel, a popular tool steel, possesses exceptional properties that make it highly sought after in various industries.

In this blog post, we will cover the key aspects of A2, including its hardness, heat treat process, hardening capabilities, knife applications, and reliable suppliers.

By understanding the features of A2, professionals and enthusiasts can harness its potential for creating durable and reliable tools.

A2 Tool Steel Hardness: Striking the Right Balance

A2 exhibits an optimal hardness, typically ranging from 59-62 HRC (Rockwell Hardness Scale).

This hardness level ensures excellent wear resistance, enabling A2 tools to withstand heavy-duty applications without excessive deformation.

The balanced hardness of A2 allows for effective machining and shaping processes during tool fabrication.

A2 Steel Heat Treat: Enhancing Performance

A2 undergoes a specific heat treat process, including heating, quenching, and tempering, to enhance its performance.

The heat treatment contributes to A2’s exceptional hardness, toughness, and wear resistance, making it suitable for demanding applications where durability and reliability are crucial.

Here is a sample of how its done with corresponding temperature ranges:

- Heat A2 to 1700 – 1900 degrees Fahrenheit in a forge or with a torch.

- Allow to cool in the air. It’s an air-hardened steel.

A2 Steel Hardening: Achieving Optimal Strength

Hardening A2 steel involves heating the material to 1700 – 1900 degrees Fahrenheit and then rapidly air cooling it to increase its hardness.

This process transforms the steel into a hardened state, improving its strength and wear resistance.

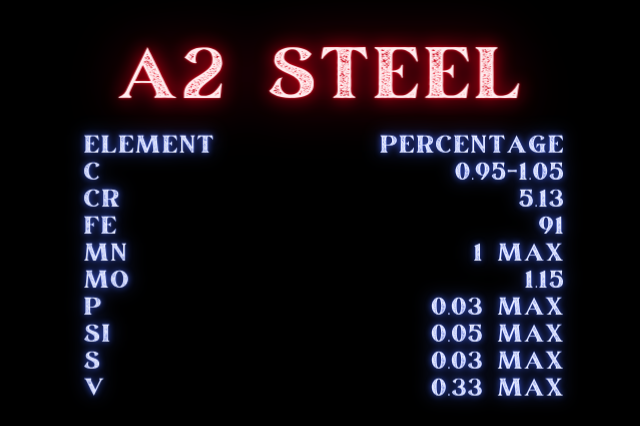

The high carbon content of A2 steel, 0.95 – 1.05%, makes it a good candidate for hardened knives and tools.

Steel Composition

To fulfill the requirements for A2, the alloy must meet the following requirements:

A2 Tool Steel Knife: A Cut Above the Rest

A2’s machinability and hardening properties make it a preferred choice for knife making.

The excellent hardness, wear resistance, and toughness of A2 contribute to the creation of durable and reliable knife blades.

A2 steel knives retain their sharpness well, ensuring prolonged cutting performance for various tasks, from everyday use to demanding outdoor applications.

A2 Tool Steel Suppliers: Reliability and Quality

When sourcing A2, it’s important to choose reliable suppliers known for their quality materials.

Reputable A2 suppliers offer consistent and authentic products, ensuring that the steel meets the necessary specifications for tool fabrication.

Our top choice for inventory is OnlineMetals.com.

Use this guide to select a piece long enough and wide enough for knife making:

- Select Material: Tool Steel

- Select Shape: Bar-Rectangle

- Select Alloy: A2

- Thickness: 0.125″ (1/8″)

- Width: 1.5″

Conclusion

A2’s exceptional hardness, reliable heat treat process, hardening capabilities, suitability for knife applications, and availability through reputable suppliers establish it as a formidable tool steel.

Understanding the distinctive features of A2 empowers professionals to create durable and high-performance tools that excel in demanding applications.