The Potential of D2 Steel

D2 steel is a renowned tool steel celebrated for its exceptional performance in various applications.

In this blog post, we will dive into the key aspects of D2, including its hardness, sharpening characteristics, Rockwell hardness, composition, and availability as bar stock.

Understanding the features of D2 allows professionals and enthusiasts to maximize its potential for creating high-quality tools.

D2 Tool Steel Hardness: A Balance of Durability and Machinability

D2 exhibits excellent hardness, typically reaching a range of 58-62 HRC (Rockwell Hardness Scale).

This optimal hardness ensures durability, enabling the steel to withstand heavy-duty applications without excessive wear.

Additionally, D2 strikes a balance between hardness and machinability, allowing for effective shaping and forming processes during tool fabrication.

D2 Steel Sharpening: Achieving an Exceptional Cutting Edge

Sharpening D2 requires careful consideration due to its high hardness.

Employing the appropriate sharpening tools and techniques, such as diamond stones or ceramic sharpening rods, ensures effective restoration of the cutting edge.

Regular maintenance and proper sharpening practices help maintain the optimal sharpness and cutting performance of D2 tools.

D2 Steel Rockwell Hardness: Testing the Steel’s Resilience

D2 typically achieves a Rockwell hardness of 58-62 HRC, making it a robust and resilient tool steel.

The Rockwell hardness test measures the steel’s ability to resist deformation and withstand applied forces, highlighting D2’s capacity to endure demanding applications and maintain its structural integrity under high-stress conditions.

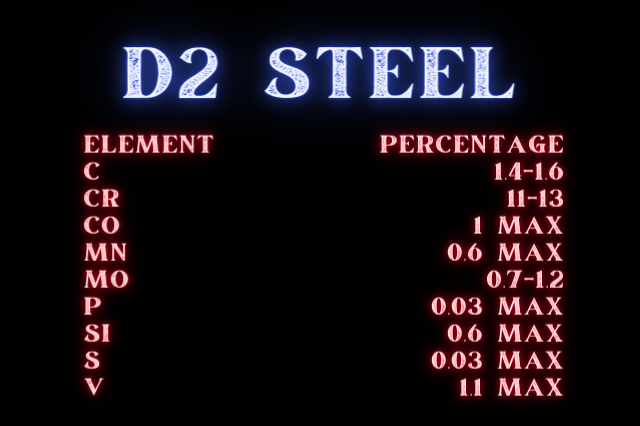

D2 Steel Composition: Alloying Elements for Enhanced Performance

D2 is composed of carbon, chromium, molybdenum, vanadium, and other alloying elements.

The precise composition contributes to its exceptional hardness, wear resistance, and toughness.

The high chromium content enhances corrosion resistance, while molybdenum and vanadium improve strength and toughness.

This well-balanced composition makes D2 a popular choice for manufacturing cutting tools, dies, punches, and other high-performance applications.

D2 Steel Bar Stock: Versatile Material for Tool Fabrication

D2 is widely available as bar stock, providing manufacturers and craftsmen with a versatile material for tool fabrication.

*We recommend the selection at OnlineMetals. We’ll detail how to make a selection below.

D2 bar stock allows for the production of custom-sized tool blanks, providing flexibility in creating tools tailored to specific applications.

Its availability as bar stock streamlines the manufacturing process, ensuring efficiency and convenience for tool makers.

Conclusion

D2 steel’s exceptional hardness, sharpening characteristics, Rockwell hardness, precise composition, and availability as bar stock establish it as a formidable tool steel.

Understanding the distinctive features of D2 empowers professionals to create durable, high-performance tools suited for a wide range of demanding applications.

How to Buy D2

First, go to OnlineMetals. Then follow the selection steps below:

- Select Material: Tool Steel

- Select Shape: Bar-Rectangle

- Select Alloy: D2

- Thickness: 0.125″ (1/8″)

- Width: 1.5″ (this gives you plenty to work with)