So you’ve already decided that you prefer gas forges over coal. You like how easy they are to light, keep lit, and manage the temperature with.

But maybe you’re not sure how far your money can go.

Let’s break down five gas forges you can buy for under $500.

We’ll talk about pros and cons of each and where to buy them starting with the most expensive first.

Affiliate disclosure: This site contains affiliate links for which I may be compensated.

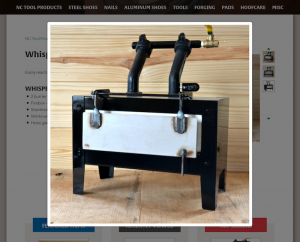

1. Whisper Deluxe Gas Forge – NC Tool Co. – $498.00

This is a double-burner gas forge with a stainless steel door.

Firebox dimensions are 3″ x 12″ x 6″.

The hose, regulator, and gauge are included.

What I Like About This Forge

This forge is very similar to the first gas forge I ever owned.

I bought it from the resident blacksmith at the John C. Campbell Folk School way back in 2011.

Being a used forge, it cost me around $225. I used it for about three years and it survived multiple moves across the country and around the Northwest.

Never had a single issue with it. Easy to light, it got hot, and it stayed hot. A great way to start off blacksmithing on your own.

I made my first few hundred hooks with it.

Sold it to a guy in Corvallis, OR for close to my purchase price to free up space for my next move.

Possible Drawbacks

This is right at the threshold of $500. If you include shipping costs from NC Tool Company in Pleasant Garden, North Carolina you’re a little above the mark.

I’ll use a Southern Indiana zip code to get a shipping estimate:

From 27313 to 47404, I’m looking at $23.65 for shipping. My total would be $521.65. That’s for 2-Day UPS Ground.

Let’s see if we can get the price a little lower, though.

2. Whisper Baby Gas Forge – NC Tool Co. – $465.00

Also from NC Tool Company, the Whisper Baby is a good portable forge with a single burner.

The new design has a port on each end to allow longer pieces to pass through end-to-end.

Firebox size is 3″ x 7″ x 6.5″ making it just over half as wide and half an inch deeper. More of a square firebox shape.

Hose, regulator, and gauge all included.

It should be noted that NC Tool Company makes most of their forges to suit farriers. Many of the forges are built to be mobile, easy to lift, just big enough to do the job.

However, a farrier’s forge can easily be a knife maker’s forge or a traditional blacksmith’s forge. If it gets it hot, it will work.

What I Like About This Forge

- It’s small so it will get up to heat quickly.

- It’s lightweight so it’s easy to move if you need to store it.

- NC Tool Company has a long history of making quality forges and anvils.

Possible Drawbacks

Depending on what you’re forging, this may be too small. Most knives will fit great. Hooks are no problem.

But if you’re trying to do something large and/or ornamental, you’ll have some trouble.

Next, let’s see if we can find a less expensive forge with more burners and a little more room.

3. Three Burner Knifemaker Deluxe – Majestic Forge – $450.00

I prefer two burners for what I do, but I thought I’d throw in a three burner for comparison.

The forge box is 18.25″ long by 9″ wide and 7.5″ high.

The firebox (interior) is 18.25″ x 6″ x 4.5″.

Full pass-through for long pieces (swords, fence pickets, etc.).

Control valves on each burner so you can keep your heat localized.

I currently use a Two Burner Knifemaker Economy Forge from Majestic (see below). It’s a great forge so I’m confident that this bigger one is too.

To set this forge up, all you will need is a propane tank. The regulator, hose, and gauge are included.

Majestic says “Setup usually takes less than 10 minutes and is very simple. Full setup instructions are included.” – MajesticForge.com

What I Like About This Forge

Majestic forges get hot! The one I have in the shop can get up to forge-welding temperature if needed. Great on conservation for production work.

I generally can get a single 20 lb. propane tank to last 6-10 hours depending on what I’m doing. At $12ish per fill, that’s $1.20 – $2.00 per hour. Excellent.

Possible Drawbacks

Three burner forges will go through gas pretty fast. Keep that in mind when considering what to buy.

Let’s get a little more economical and see what else Majestic has.

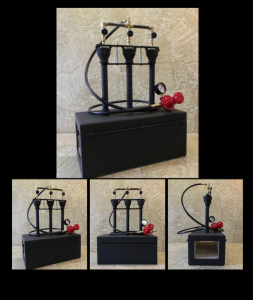

4. Two Burner Knifemaker Economy – Majestic Forge – $325.00

This is the forge I currently own. I bought it in March of 2019 for $325 plus around $50 shipping.

Two burners with a factory rigidized vacuum-formed ceramic liner. High siliconized ladle brick on the bottom. Very durable interior.

Overall dimensions (without top burners): 13.75″ x 9″ x 7.5″

Firebox (interior): 13.5″ x 6″ x 4.5″

Full pass-through for longer pieces. I’ve only run into issues with pieces longer than 20 inches. They don’t balance well if you have the tip of the piece inside the forge.

The solution is to have a forge rest to prop up the end that’s outside the forge.

What I Like About This Forge

I like the price, the durability, and the fuel conservation. Solid forge all-around and durable enough for a full-time blacksmith’s shop.

I use this forge to teach 100 – 200 students each year and it holds up under their use.

Possible Drawbacks

A little on the short side for very long pieces as I mentioned above.

No control valves for the individual burners. You’ll have to control both with the main regulator.

Running it at 4-5 psi will do great for upwards of 6 hours depending on atmospheric conditions in your shop.

*This would be my choice for a beginner’s forge. I talk about it in the Blacksmith Starter Kit article.

Now let’s look at an unknown (to me) forge that’s just under $300 and has a great deal on shipping.

5. Atlas Single Burner Knifemakers Forge – $295.00

This one is a gem of a forge and it’s reasonably priced.

From their description:

“The best forge for bladesmithing! Compared to the forges on eBay/Amazon, it gets hotter, the insulation will last longer, it won’t rust, and it only uses $1 propane per hour!”

Overall Dimensions: 12″ x 12″ x 6″

Firebox Dimensions: 2.5″ diameter x 11″ long (cylindrical chamber)

Stainless steel. Comes with a regulator and hose.

Purchase from Centaur Forge.

What I Like About This Forge

I’m a sucker for stainless steel and compact forges. The Atlas Single Burner weighs 19.8 pounds total.

It also has a sliding tool rest. That’s tricky to do on a compact forge.

The price is impressive as well. Shipping from Centaur Forge is only an additional $14.95 Flat Rate (Flat Rate shipping is one of the reasons I love Centaur Forge).

Possible Drawbacks

It’s very small. The chamber is just 2.5 inches across so you’re probably making one thing at a time.

That said, you’re going to save a lot of fuel in such a small firebox.

That nice stainless steel will likely get a tempering rainbow fairly quickly as it heats up.

Nothing too major here. Heck, and at that price I might buy one just to see how it does.

The Verdict

You can get a durable, high quality gas forge for less than $500. If you take good care of it, you’ll be able to pass it down to your great-grandkids.

For my money, I would go with either the NC Tool Co. Whisper Deluxe or the Majestic Forge Two Burner Knifemaker Economy.

I’ve owned both of them and they’ve kept my business running for years.

Have you found a good deal on a gas forge (used or new)?

Leave the story in the comments below. Your experience can help others.

Cheers,